Properties of Fast Hydration Guar Gum, Its Benefits And Applications

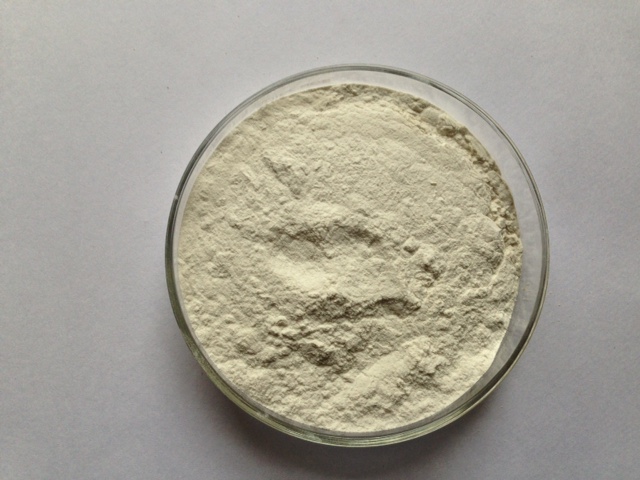

What is fast hydration guar gum powder?

Fast hydration guar gum powder is a powder that is manufactured by grinding and crushing guar beans into powder, which is mainly found in India, china, Australia and Pakistan. It is a polysaccharide that is relatively soluble, has high viscosity and a high thickening ability which makes it very useful when used as an emulsifier.

Comparison of fast hydrating guar gum powder with regular guar gum powder

Fast Hydrating Guar Gum Powder is much more effective than normal guar gum powder in providing viscosity. Within merely three minutes, Fast Hydrating Guar Gum Powder starts giving viscosity, while it takes regular guar gum powder almost two hours to do the same. Thus, Fast Hydrating Guar Gum Powder saves much time and resources, leading to more profits when used in the oil and gas drilling process.

Fast Hydrating Guar Gum Powder is much more effective than normal guar gum powder in providing viscosity. Within merely three minutes, Fast Hydrating Guar Gum Powder starts giving viscosity, while it takes regular guar gum powder almost two hours to do the same. Thus, Fast Hydrating Guar Gum Powder saves much time and resources, leading to more profits when used in the oil and gas drilling process.

Properties of Fast Hydrating Guar Gum Powder

Fast Hydrating Guar Gum Powder is a fine white powder, soluble in water and with a pH of 5 to 8. It has moisture of 7% maximum. Fast Hydrating Guar Gum Powder is a very good soluble, thus making it a good stabilizer. It is best used in a pH range of 5-7, because its high viscosity reduces significantly in a condition of very high alkalinity or acidity. It has a thickening capability that is 8 times that of water. This makes it very useful when used as an emulsifier. Fast Hydrating Guar Gum Powder is very stable in very low, freezing temperatures, thus can prevent growth of ice crystals, while at the same time working at optimum levels. It achieves viscosity at a very short period of 3 minutes.

Applications of Fast Hydrating Guar Gum Powder in Oil and Gas Industries

Fast Hydrating Guar Gum Powder is very useful in oil and gas industries. In the oil industry, it is used as a synthetic polymer, a surfactant and a defoamer because it is ideal for all the  rheological requirements necessary in water-based and brine-based drilling fluids. In the oil industry, Fast Hydrating Guar Gum Powder is used to regulate the viscosity of the mud solution, hence stabilizing and regulating the flowing properties of the drilling muds. In the oil and gas industries, it is also used to help diminish the friction in the holes, hence reducing the usage of power. It is also used to reduce the losses of water that can occur in a broken geological formation. Fast Hydrating Guar Gum Powder is also used to cool drilling bits, cementing slurries and continuous fracturing in the oil and gas drilling industries.

rheological requirements necessary in water-based and brine-based drilling fluids. In the oil industry, Fast Hydrating Guar Gum Powder is used to regulate the viscosity of the mud solution, hence stabilizing and regulating the flowing properties of the drilling muds. In the oil and gas industries, it is also used to help diminish the friction in the holes, hence reducing the usage of power. It is also used to reduce the losses of water that can occur in a broken geological formation. Fast Hydrating Guar Gum Powder is also used to cool drilling bits, cementing slurries and continuous fracturing in the oil and gas drilling industries.

Conclusion

Fast Hydrating Guar Gum Powder has very useful physical and chemical properties which make it very useful in the oil and gas drilling industries, as well as the food sector. As long as it is used in conditions of pH value of 5-7, it will help to enhance viscosity, lubricate and reduce water loss, thus reducing costs and enhancing productivity. It is very economical, and its usage is set to rise exponentially as more developing countries start oil and gas drilling exploitations to develop their economies. For more information about fast hydrating guar gum powder please visit: https://www.altrafine.com/fast_hydration_guar_gum_powder.html.

This Article has been written & posted by Ajit Patel.