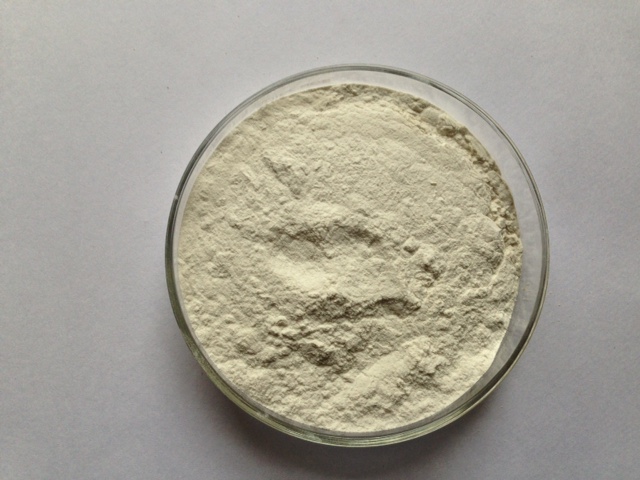

The Sesbania gum plant is found in the monsoon regions of Asian countries. It is a plant that can grow up to 2 meters high and is marked by large flowers available in a range of bright colors like white, yellow or pink.  The Sesbania gum is extracted from seeds in Asia by carefully removing the husk, cotyledons and other germ materials from the seed, thus exposing the clean splits which are then milled in a mesh, resulting in a pure and refined Sebastian gum. Other names for this plant are Dhaincha and Jantar. The plant thrives well in highly alkaline soils and even water logged areas. The plant adapts well to hot and humid environment. It has tough and stout stems and the plant is able to withstand unfavorable weather conditions that would otherwise be detrimental to other plants.

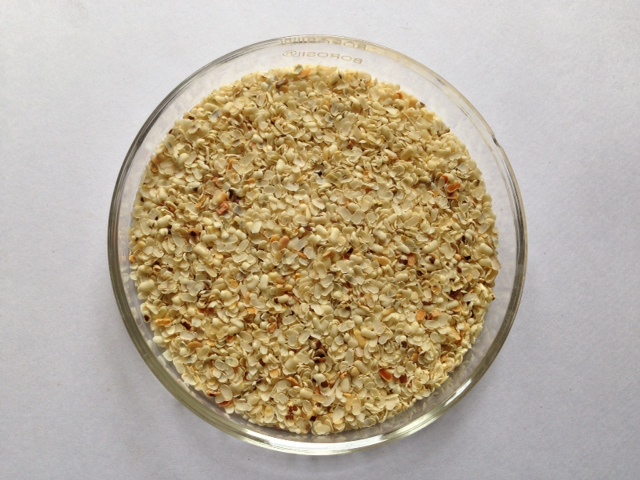

The Sesbania gum is extracted from seeds in Asia by carefully removing the husk, cotyledons and other germ materials from the seed, thus exposing the clean splits which are then milled in a mesh, resulting in a pure and refined Sebastian gum. Other names for this plant are Dhaincha and Jantar. The plant thrives well in highly alkaline soils and even water logged areas. The plant adapts well to hot and humid environment. It has tough and stout stems and the plant is able to withstand unfavorable weather conditions that would otherwise be detrimental to other plants.

Uses and properties of Sesbania gum powder

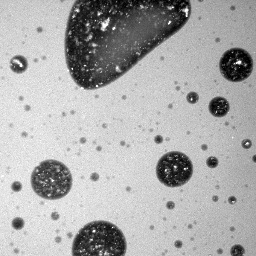

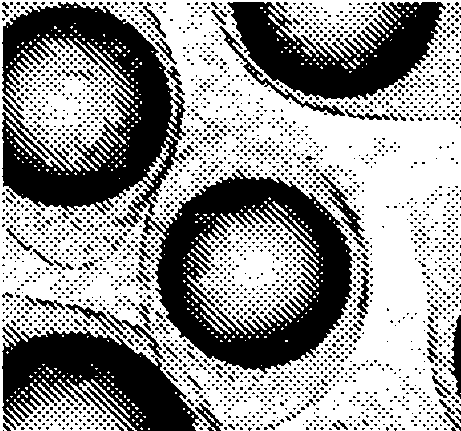

Sesbania gum has similar characteristic to other natural gums. However depending on climate and concentrations, the gum may behave differently. Under higher concentrations, Sesbania may behave like the guar gum .Sesbania gum is highly soluble in water and has a high viscosity rate thus the reason for its preference in textile industries. Sesbania gum powder is used as a thickening agent or dye agents in textile industries. Due to its high soluble rate, it is widely used in the treatment of waste water. The gum plays a major role in the oil industry in various areas thus increasing the overall oil production and increasing sales.

Advantages of Sesbania over Guar gum powder

Guar gum powder was widely used as a thickening agent in numerous industrial fields. However its popularity is declining due to the scarcity of its material thus making the product very expensive to obtain. However Sesbania plant grows in alkaline soils and therefore cheap to produce since no crop displacement is required for its cultivation. Sesbania Gum can be produced at a cheaper cost than the Guar gum. Moreover Sesbania gum does not degrade even at very high temperatures whereas the Guar gum degrades. The Sesbania gum is 5 times higher viscous than the Guar gum. Although the Guar gum powder has been used in large quantities in the petroleum industry, studies have revealed that even the Sesbania gum powder is able to fully perform similar functions. Therefore most industries are now replacing their Guar gum use with Sesbania powder.

Conclusion

In this industrialized world, gum use is increasingly becoming useful in various industries. As research continues people are on the lookout for the most efficient gum available. Studies have revealed that Sesbania Gum powder is now preferred to Guar gum powder due to its desirable properties. The viscosity and solubility rate of the Sesbania gum powder is 5 times higher than most natural gums in the market. The issue of cost also comes up since it is much cheaper to produce Sesbania Gum powder. Apart from industrial use the powder is also used as incense. Therefore it has proved to be a truly better replacement. Know more about sesbania gum powder please visit: https://www.altrafine.com/sesbania-gum-powder.html

This Article has been written & posted by Ajit Patel.