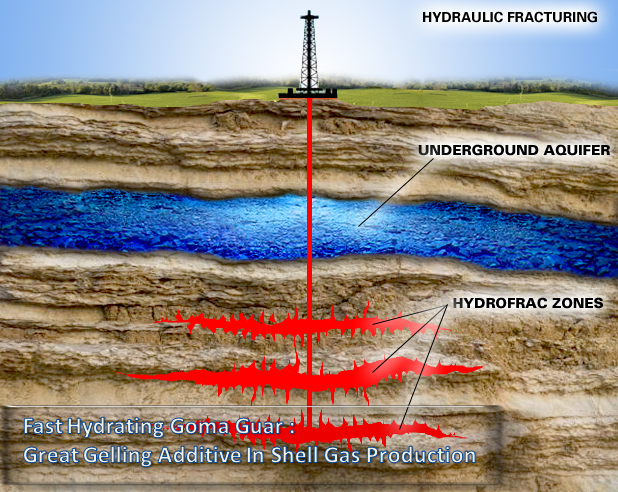

Innovation is critical to development, and this has been proven in oil and gas production. For oil to fully develop in aquifers, it takes a long time and there would be a great scarcity of the product. Therefore fracturing techniques and the discovery of the goma guar have been instrumental in increased oil production.

Global Use In Gas Production

The global rush in oil exploration and production has put increased demand on the production and processing of the goma guar. In the united states alone the demand for the product is over 300,000 metric tones per year. In the fracturing process, it is estimated than one oil well consumes an average 9 metric tonnes. This demand is set to rise as oil production companies engage in the fracking process to gets as much as possible from a well.

Processing For Hydraulic Fracturing

To improve the flow characteristic, chemical modification of the structure is necessary. It leads to the formation of a structure containing both hydrophobic and hydrophilic chains. Cost considerations are made while determining how to modify the original product. Crosslinking is the preferred method than increasing the amount of the polymer in the fluid. Studies have observed a universal concept in hydration of polymers; When a soluble polymer gets hydrated, the viscosity increases with increasing concentration exponentially. Cross linking is done using borate to achieve the required flow characteristics.

Color and Purity of the Goma Guar Powder

The color and purity of the Fast Hydration Guar Gum Powder is an indicator of the level of purity. Product used in the oil field industry has a white to off white color, thus highly purified. The quick hydrating pale white powder exhibits very high viscosity and used in oil drilling as a friction reducer for easier rotation of the drill bit as well as a hydrating agent.

Where can you get Goma guar?

With the seeming rush for the product, a good, stable and reliable supply is important. The capacity of a supplier and quality are critical factors to consider when looking for a constant supply. Altrafine Gums, India have a stringent quality management system for processing of the goma guar. Quality assurance and testing is done continuously to ensure the end product meets customer specifications.

Packaging and Delivery Methods of Goma Guar Powder

Multiple market requirements have prompted manufacturers to develop innovative packaging and delivery models. Packaging is done in consideration of factors such as stacking, transport and storage conditionsas well as to avoiding atmospheric contamination. The product is packed in multi walled bags that do not easily break even under tension or compression forces.

Guar Powder Application In Hydraulic Fracturing Additives

The shell or sedimentary rock contains mud, rock and organic matter. Left alone to release gas and hydrocarbons would require thousands of years. To hasten this process, vertical, horizontal drilling and hydraulic fracturing is done. In fracturing, water, sand and additives are pumped under high pressure to create cracks in the rock. Goma guar thickens the water, allowing the sand to be suspended for delivery to the cracks. The sand causes cracks to remain open and allow crude to flow to the well bore.

Conclusion

Goma guar has gained global usage in the oil production industry. The demand continues to grow as the hydraulic fracturing process becomes the way to go for oil and gas exploration. It is fast hydrating and easily combines with water to create a thick liquid best for the oil fracturing process.

This Article has been written & posted by Ajit Patel.