Altrafine Gums stands at the forefront of the hydrocolloids and natural gums industry, offering a wide range of products, including food-grade thickeners, gelling additives, stabilizing agents, and emulsifying additives. In a highly competitive market filled with synthetic substitutes and various additives, Altrafine Gums presents products that not only compete but often surpass existing solutions in terms of quality and effectiveness.

State-of-the-Art Infrastructure and Innovative Technology

Altrafine Gums prides itself on having state-of-the-art infrastructure capable of producing top-tier products that meet the highest quality standards. The company’s dedicated team of professionals continuously seeks out new technologies and methods to enhance product quality. This relentless pursuit of innovation and excellence drives Altrafine Gums to remain a leader in the industry.

Commitment to Quality and Customer Satisfaction

At the heart of Altrafine Gums is a consumer-centric approach, aiming to satisfy clients from diverse industries. The company is committed to delivering products with uncompromising quality control and prompt services. Each product undergoes rigorous environmental and chemical testing by skilled personnel, ensuring it meets the bacteriological standards crucial for the food processing industry.

Global Recognition and Industry Leadership

Setting groundbreaking milestones, Altrafine Gums has been recognized as the first award winner in Gujarat for being the biggest exporter in the industry. With over 41 years of experience, the company has set benchmarking standards that other businesses in the same line strive to achieve.

Extensive Export Network

The quality of Altrafine Gums’ products is testified by its extensive export network, reaching numerous countries worldwide. From the United States to the United Kingdom, and from Algeria to Argentina, Altrafine Gums’ presence is felt globally. The company’s products are highly sought after in diverse markets, including Australia, Bangladesh, Belarus, Belgium, Bolivia, Brazil, Bulgaria, Burkina Faso, Canada, Chile, China, Colombia, Costa Rica, Czech Republic, Denmark, Dominica, Ecuador, Egypt, Estonia, Ethiopia, Finland, France, Germany, Greece, Guatemala, Honduras, Hong Kong, Hungary, Indonesia, Ireland, Italy, and Japan, among many others. This global presence underscores the trust and demand for Altrafine Gums’ products, demonstrating the company’s ability to meet the diverse needs of international clients.

Rigorous Quality Assurance

Quality is the cornerstone of Altrafine Gums’ operations. The company ensures that all Guar Gum products undergo thorough inspections and stringent quality tests at every production stage. This meticulous process guarantees that each product maintains the highest quality standards, irrespective of the production stage it has passed through.

Altrafine Gums’ quality assurance team is dedicated to preventing contamination at every step, ensuring that the final product remains untainted and meets the company’s high standards. During the final packaging stage, products are packed under strict hygienic conditions using high-standard packaging materials to ensure safety during transit.

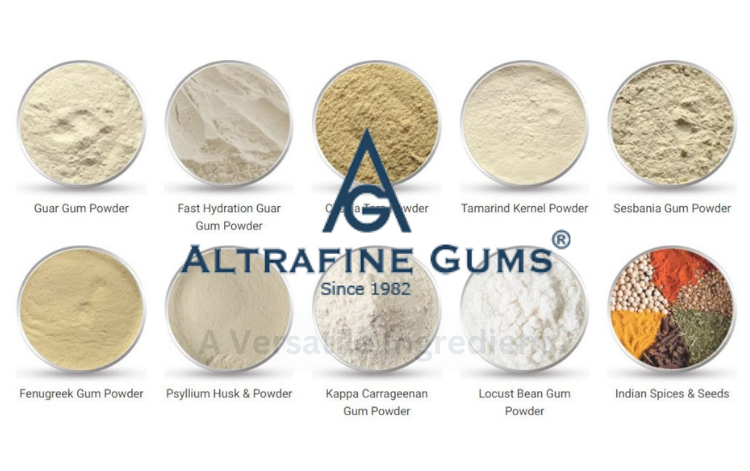

Product Range

Altrafine Gums offers a diverse range of products, including:

- Guar Gum Powder: A natural thickening, stabilizing, and emulsifying agent widely used in the food, pharmaceutical, and cosmetic industries.

- Fast Hydration Guar Gum Powder: Specifically designed for rapid hydration and high viscosity, essential for applications in the oil and gas industry.

- Cassia Tora Powder: Used as a thickener and gelling agent in food and pet food industries.

- Tamarind Kernel Powder: Employed in the textile and paper industries for its thickening and sizing properties.

- Sesbania Gum Powder: Applied in various industrial applications, including textiles, oil drilling, and personal care products.

- Fenugreek Gum Powder: Known for its health benefits, used in food and pharmaceuticals.

- Psyllium Husk and Powder (Isabgol): A natural fiber supplement that aids in digestive health and is used in dietary supplements.

Unwavering Commitment to Excellence

Altrafine Gums’ commitment to excellence is evident in every aspect of its operations. From sourcing high-quality raw materials to implementing rigorous processing standards, the company ensures that its products are unparalleled in quality. The quality assurance team, with vast knowledge and expertise, plays a crucial role in maintaining the integrity of the products throughout the manufacturing process.

Conclusion

Altrafine Gums has established itself as a leader in the hydrocolloids and natural gums industry by offering superior products and maintaining rigorous quality standards. With a strong focus on innovation, customer satisfaction, and global reach, the company continues to set benchmarks in the industry. Whether it’s Guar Gum Powder, Cassia Tora Powder, or any other product, Altrafine Gums ensures unmatched quality and reliability.

FAQs – Altrafine Gums

Q1: What types of products does Altrafine Gums offer?

Altrafine Gums offers a range of hydrocolloids and natural gums, including Guar Gum Powder, Fast Hydration Guar Gum Powder, Cassia Tora Powder, Tamarind Kernel Powder, Sesbania Gum Powder, Fenugreek Gum Powder, and Psyllium Husk & Powder.

Q2: How does Altrafine Gums ensure the quality of its products?

Altrafine Gums ensures quality through stringent quality control measures at every stage of production, rigorous environmental and chemical testing, and adherence to high standards in packaging and handling.

Q3: In which industries are Altrafine Gums' products used?

The products are used in various industries, including food, pharmaceuticals, cosmetics, textiles, oil and gas, and personal care.

Q4: What is the significance of mesh sizes in Guar Gum Powder?

Mesh size refers to the fineness of the powder. 100 Mesh Guar Gum Powder has a coarser texture, while 200 Mesh Guar Gum Powder is finer. The choice of mesh size depends on the specific application requirements.

Q5: What are the benefits of using Guar Gum Powder?

Guar Gum Powder acts as a natural thickening, stabilizing, and emulsifying agent. It enhances the texture and shelf-life of food products, aids in drug formulation in pharmaceuticals, and is used in hydraulic fracturing in the oil and gas industry.

Q6: How long has Altrafine Gums been in the industry?

Altrafine Gums has been in the industry for over 41 years, marking significant milestones and setting benchmarks in quality and innovation.

Q7: What makes Altrafine Gums a preferred supplier globally?

Altrafine Gums is preferred globally due to its commitment to quality, extensive export network, innovative technology, and customer-centric approach.

Q8: How does Altrafine Gums contribute to sustainability?

Altrafine Gums ensures sustainable practices by maintaining high standards in raw material sourcing, reducing environmental impact during production, and ensuring safe and hygienic packaging.