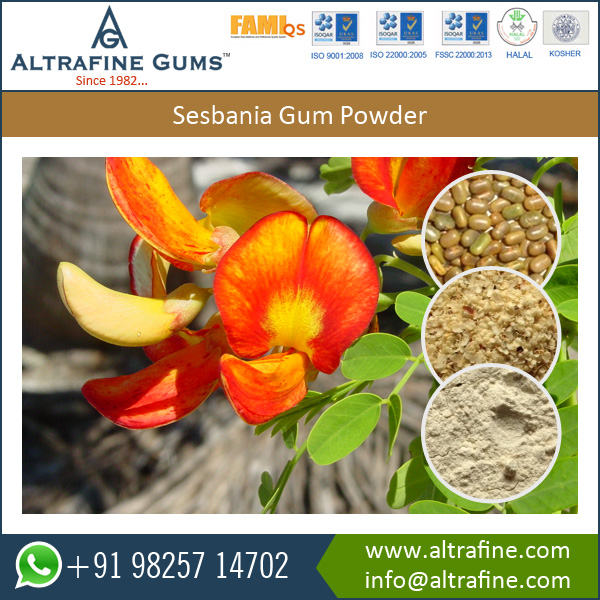

In this scientific and technological world research shows that there are wide variety of gum powder are been used for variety of purposes with its medicinal benefits. One of them is the Sesbania Gum Powder which is mainly been extracted from the sesbania seeds . Sesbania is an annual plant which mainly grows in China, Asia and Africa. The Sesbania Gum Powder has several different uses, like it is been used as dye thickener in the textile industry as wells as used for making incense. It is been used as blocking agent hence helps in the waste water treatment.

There are also uses of Sesbania Grandiflora which is been used to produce this gum powder. Sesbania Grandiflora or sesban is also known as vegetable hummingbird, agati, or the hummingbird tree.

Appearance and Medicinal Properties: Sesbania Grandiflora consists of leaves and big flowers. The leaves are rich in iron, calcium, carbohydrate, protein, fiber, fat, vitamin B1, vitamin A and vitamin C and essential amino acids etc. The flowers are white, red and yellow in color which rich in vitamin A&B, iron and calcium and the fruit can also be taken as vegetable. Useful parts of plants for medicinal purpose:

Useful parts of plants for medicinal purpose:

Following are the parts of the Sesbania Grandiflora which are been useful in the field of medicine

- Flowers

- Leaves

- Bark

- Roots

- Fruits

This plant has its medicinal properties, and medicinal uses which will help you to cure different diseases.

- Sesbania Grandiflora has aperients, diuretic, emetic, emmenagogue, febrifuge, laxative, tonic properties which helps to cure many ailments externally as well as internally.

- Externally it helps to cure most of the skin diseases including with the bites of poisonous insect animals as well as can also be applied on the rheumatic joint. Root bark is helpful in gaining relief in the pain for rheumatic joint.

- Internally, it is been used to cure cold and cough, fever in the body or extensive heat, jaundice etc.

- The juice of flower been made helps to cure with the vision problems like night blindness or any other eye diseases. It is also been used to cure the migraine problem.

- It cures stomach disorders in children as well as in new born baby.

- Because of its laxative medicinal properties it checks for anemia, tumor and also helps to improve memory. Leaves are been used to cure the oral and throat infections.

- To relieve pain and inflammation associated with arthritis roots and barks paste is been applied externally.

- Leaf juice is been used as nasal drops to relieve headache and remittent fever.

- Roots when taken with honey help to cure catarrh.

- Leaves are sweet, cooling which are also been used to make tea which also helps to cure nasal catarrh.

There are also other uses of Sesbania Grandiflora where the pulp of the wood is been used to make paper. The old trees are been used in house construction as well as used as poles. In fact, rather than the other uses it makes a more impact on the medicinal properties.