Industrial Grade Guar Gum Powder: The Backbone of Efficient Drilling in the Oil & Gas Industry

Table of Contents

Industrial-grade guar gum powder is a high-quality, natural polysaccharide that is widely used in various industrial applications, including the oil and gas industry. Derived from the seeds of the guar plant, it has a unique set of chemical properties that make it highly effective in a variety of applications, especially in the oil and gas sector.

In its industrial-grade form, guar gum is primarily used for its ability to enhance fluid viscosity, a critical factor in oil extraction and fracking (hydraulic fracturing) operations. Its versatility and cost-effectiveness have made it a preferred choice in the industry, particularly in areas that require stable and efficient fluid dynamics. The powder plays a vital role in enabling the efficient extraction of oil and gas from deep underground reserves.

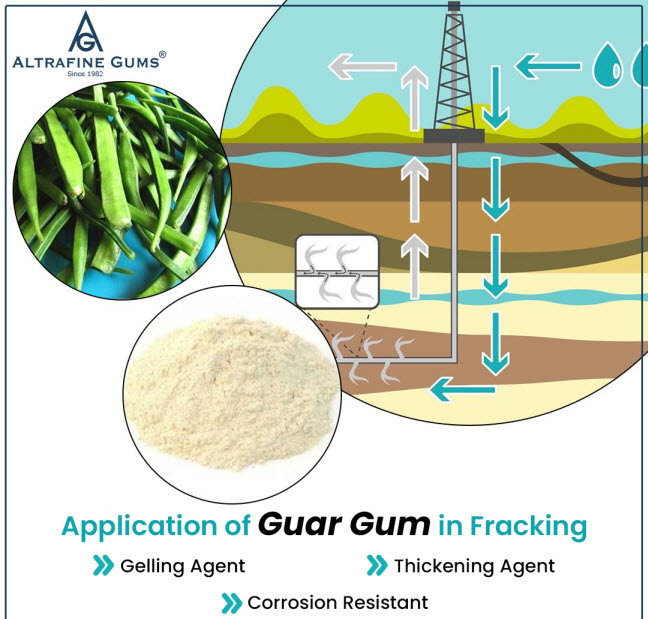

Applications in Hydraulic Fracturing (Fracking)

Guar gum is a key ingredient in the fracking process, where it is used to enhance fluid viscosity. Hydraulic fracturing involves injecting a mixture of water, chemicals, and sand into underground rock formations at high pressures to fracture the rock and release trapped oil and gas. The addition of guar gum increases the thickness of the fluid, ensuring it has the right consistency to effectively carry the sand particles into the fractures in the rock.

Role of Guar Gum in Enhancing Fluid Viscosity for Fracking

The primary role of industrial-grade guar gum in fracking is its ability to thicken the fracturing fluid, making it more effective at carrying the proppant (usually sand) into the fractures. By increasing the viscosity of the fluid, guar gum ensures that the fluid remains in place longer, helping the fracturing process reach deeper layers of rock. The increased viscosity also enhances the flow-back control, reducing the loss of proppants and chemicals during the operation.

Ensuring Stable and Efficient Oil Extraction Processes

In the oil extraction process, the efficiency of fracking depends on maintaining a stable flow of fracturing fluids into the rock formation. Guar gum powder contributes to the stability of these fluids by maintaining their viscosity throughout the fracking process. This results in a more stable and efficient oil extraction operation, reducing downtime and increasing productivity.

By improving the fluid’s performance, guar gum helps ensure that the process runs smoothly, making it indispensable in enhancing the overall efficiency of oil extraction and fracking operations.

Advantages of Industrial Grade Guar Gum in Oil & Gas

The use of industrial-grade guar gum in the oil and gas industry offers several key advantages, making it an essential component in oil extraction and fracking. From its cost-effectiveness to its eco-friendly properties, the benefits of guar gum in this sector are undeniable.

Cost-effectiveness and Eco-friendly Properties

One of the major advantages of industrial-grade guar gum is its cost-effectiveness. Compared to other chemical additives used in hydraulic fracturing, guar gum is relatively affordable, making it a preferred choice for companies aiming to minimize the costs of their fracking operations. The low cost, combined with its high efficacy, provides a cost-effective solution for enhancing oil extraction processes.

Additionally, guar gum is a natural product, which makes it a more eco-friendly option compared to synthetic alternatives. Its biodegradability ensures that it has minimal environmental impact, making it a better choice for companies aiming to reduce their carbon footprint and adhere to environmental regulations. As sustainability becomes increasingly important in the oil and gas industry, the demand for eco-friendly additives like guar gum is likely to continue growing.

Improving Operational Efficiency and Reducing Environmental Impact

By improving the viscosity of fracking fluids, guar gum powder helps increase the overall operational efficiency of fracking processes. This not only leads to more efficient extraction but also reduces the need for additional chemicals and resources, contributing to environmental sustainability.

Furthermore, its biodegradability ensures that guar gum has minimal impact on the surrounding environment once the fracking process is complete, contributing to the overall reduction of environmental hazards in oil and gas operations.

Global Demand and Supply Dynamics

The demand for industrial-grade guar gum in the oil and gas industry is growing globally, driven by the expanding need for efficient and eco-friendly solutions in hydraulic fracturing. As the oil and gas industry continues to thrive in various regions around the world, the demand for guar gum is expected to rise significantly.

Key Markets for Industrial-Grade Guar Gum in the Oil & Gas Industry

Industrial-grade guar gum is primarily used in regions with active oil and gas exploration, particularly in areas where fracking is a common practice. Key markets for guar gum in the oil and gas industry include:

- North America: Particularly the United States and Canada, where hydraulic fracturing is widely used in shale gas and tight oil reservoirs.

- South America: Brazil and Argentina are emerging markets for fracking and oil extraction.

- Middle East and Africa: Oil-rich countries such as Saudi Arabia, the UAE, and Algeria are significant consumers of guar gum in their oil extraction processes.

- Asia Pacific: Countries like China and India are also witnessing growing demand for guar gum as the oil and gas industry expands in these regions.

Export and Sourcing Trends Across Regions

The global demand for industrial-grade guar gum is also influenced by the export dynamics of guar gum powder. India is the leading exporter of guar gum, with a major portion of its exports directed towards oil and gas companies in North America and the Middle East. The increasing demand for natural and eco-friendly additives in the oil and gas sector is expected to drive more international trade of guar gum, particularly as the demand for hydraulic fracturing continues to grow.

The Future of Industrial Grade Guar Gum in Oil & Gas

The future of industrial-grade guar gum in the oil and gas industry looks promising, with several exciting developments on the horizon. As oil extraction technologies advance and environmental concerns continue to rise, the role of guar gum in hydraulic fracturing is expected to evolve.

Innovations in Guar Gum Applications for Deep-Sea Drilling and Enhanced Oil Recovery

With the growing demand for deep-sea drilling and enhanced oil recovery (EOR) methods, industrial-grade guar gum is becoming increasingly important. Innovations are being made to improve its performance in these advanced oil extraction techniques. Research into modifying the chemical properties of guar gum to make it even more efficient in challenging environments is underway, and these innovations will likely lead to new applications for guar gum powder in offshore drilling and EOR operations.

Market Forecast and Industry Growth Opportunities

The global market for industrial-grade guar gum is expected to continue growing as the oil and gas industry expands its exploration and extraction operations. As the demand for eco-friendly and cost-effective solutions increases, guar gum will continue to play a vital role in the fracking process. The market is expected to see significant growth in regions like North America, South America, and the Middle East, where hydraulic fracturing remains a critical method for oil and gas extraction.

Conclusion

Industrial-grade guar gum powder plays an indispensable role in the oil and gas industry, particularly in hydraulic fracturing. Its ability to enhance fluid viscosity, improve operational efficiency, and reduce environmental impact makes it a crucial component in modern oil extraction methods. As demand for eco-friendly and cost-effective solutions continues to rise, the future of guar gum in the oil and gas industry looks bright, with opportunities for innovation and growth in key markets.

Contact Us Today!

For high-quality industrial-grade guar gum powder, Altrafine Gums is your trusted partner. As a leading manufacturer of guar gum powder in India, we specialize in providing top-grade guar gum for the oil and gas industry. Contact us, call us now, or chat with us to learn more about our products and how we can meet your specific requirements for efficient and sustainable drilling operations.

FAQs About Industrial Grade Guar Gum Powder

1. What is industrial-grade guar gum powder, and why is it used in oil extraction?

Industrial-grade guar gum powder is a natural polysaccharide used to enhance fluid viscosity in the hydraulic fracturing process. It helps carry proppants into the fractures of rocks, improving the efficiency and stability of oil extraction.

2. How does guar gum improve the hydraulic fracturing process?

Guar gum increases the viscosity of fracking fluids, allowing them to effectively carry proppants into fractures. It ensures the fluid has the right consistency for better fracturing and oil extraction efficiency.

3. Is industrial-grade guar gum eco-friendly?

Yes, guar gum is an eco-friendly, biodegradable ingredient that reduces the environmental impact of oil and gas extraction processes, making it a preferred choice for sustainable operations.

4. What are the advantages of using guar gum in oil and gas operations?

The advantages of guar gum in oil and gas operations include its cost-effectiveness, biodegradability, ability to improve fluid stability, and enhanced operational efficiency, all contributing to more effective and environmentally friendly extraction.

5. How is the global demand for guar gum in the oil and gas sector?

The global demand for industrial-grade guar gum in the oil and gas sector is growing, particularly in regions like North America, South America, and the Middle East, driven by the increasing use of hydraulic fracturing.

6. What are the future trends for guar gum in oil extraction?

Future trends for guar gum in the oil industry include innovations in its use for deep-sea drilling and enhanced oil recovery (EOR), with advancements in its chemical properties to improve its performance in extreme environments.

7. Can guar gum be used in deep-sea drilling operations?

Yes, guar gum is being researched for its applications in deep-sea drilling and enhanced oil recovery (EOR), as it can improve fluid viscosity in challenging underwater environments, ensuring efficient oil extraction.